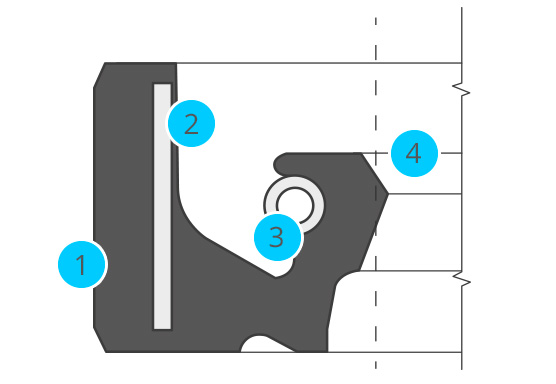

HIGH PRESSURE OIL SEALS

The rotary shaft oil seal is an indispensable component in lubricated rotating equipment and must be chosen with caution in order to ensure that the correct design and materials are used to provide a long-lasting life for the rotating equipment.

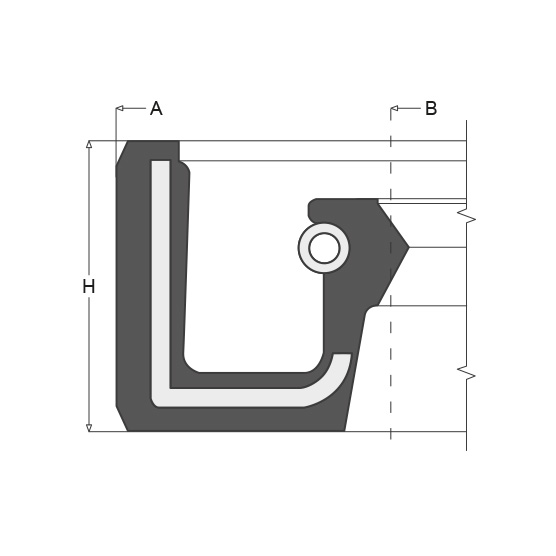

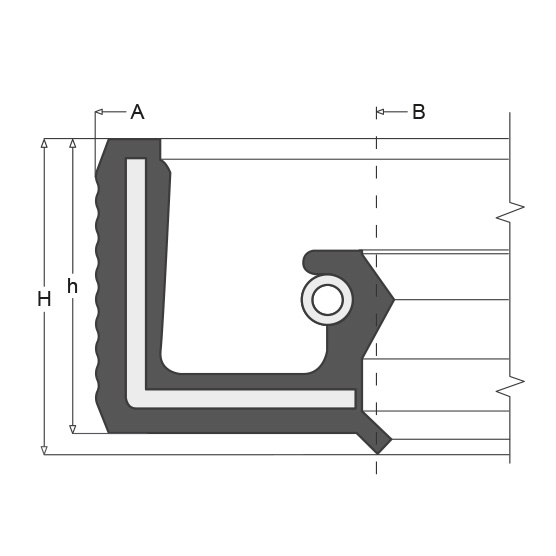

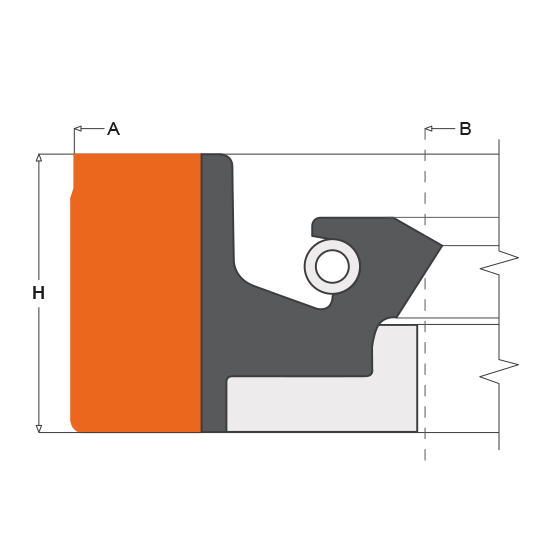

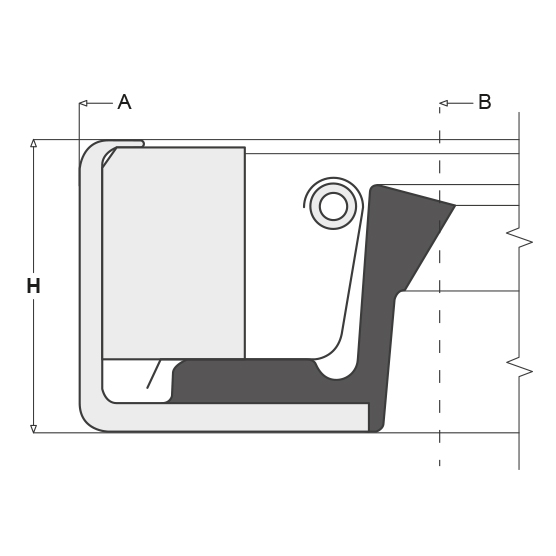

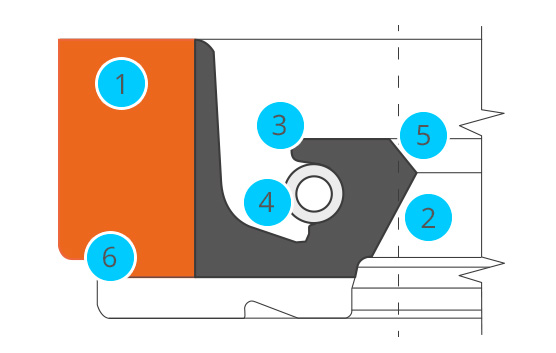

These variations of the G and M type seals are engineered to withstand pressure up to 10 BAR (1 MPa), although this limit has been exceeded in some applications. These seals are available with or without an additional dust lip. The G type and its high pressure variants show a metal insert covered by rubber, while the M type and its variants offer a bare metal body on the outside diameter.

Rotary shaft oil seal for extreme pressures:

We can supply rotary shaft oil seals for applications with up to 100 BAR (10 MPa) pressure. Our profile GHH-BP has been tested to meet these standards.

Download:

GB

MB

Technical Features

Guaranteed up to 10 BAR (1 MPa), although in some applications this limit has been greatly exceeded.

Materials

DC04; AISI 304; AISI 316

AISI 302; AISI 316; C72 phosphated

NBR; FKM; VMQ; HNBR; EPDM

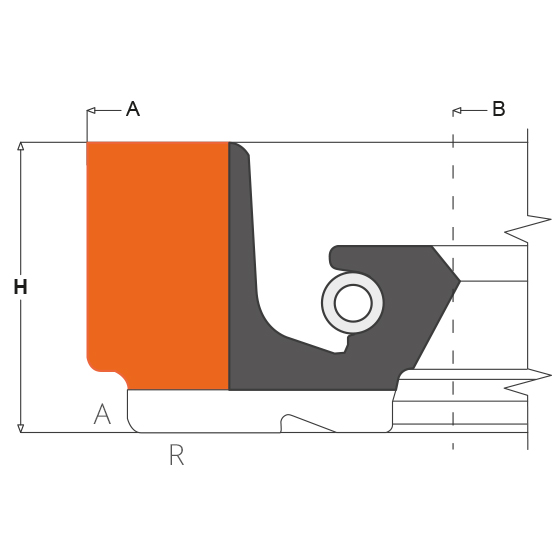

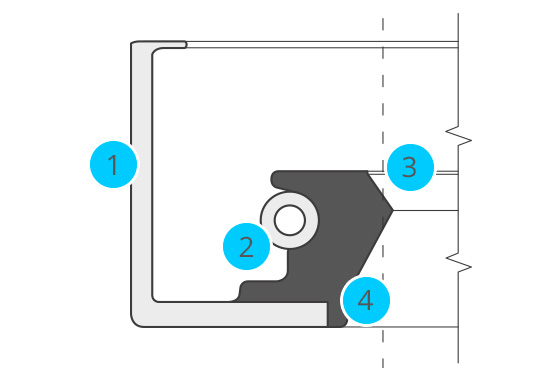

TEXTILE RUBBER OIL SEALS FOR HIGH PRESSURES

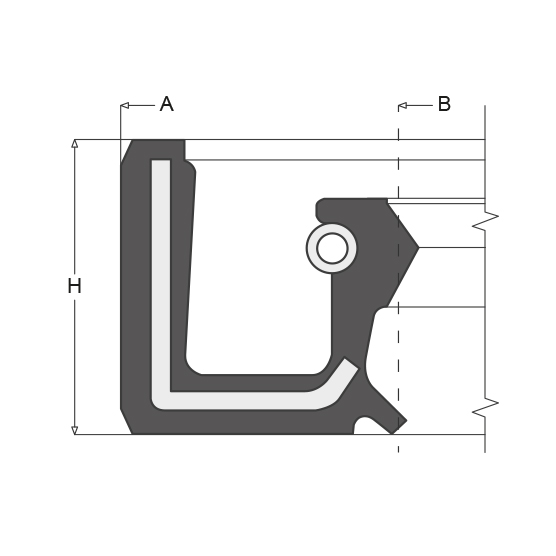

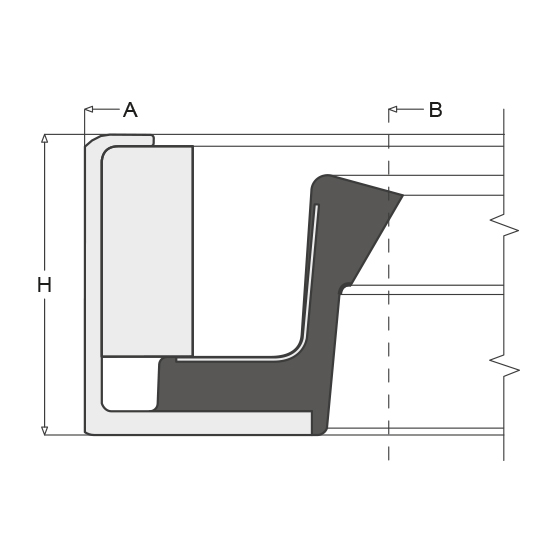

•FP• produces a full range of textile rubber oil seals designs, including the profiles for high pressure applications.

These special profiles are variations of the standard ones, engineered to guarantee excellent performance with such working conditions.

They are named with the extension BP.

Download:

TGU-BP

TGA-BP

Technical Features

Materials

AISI 302; AISI 316

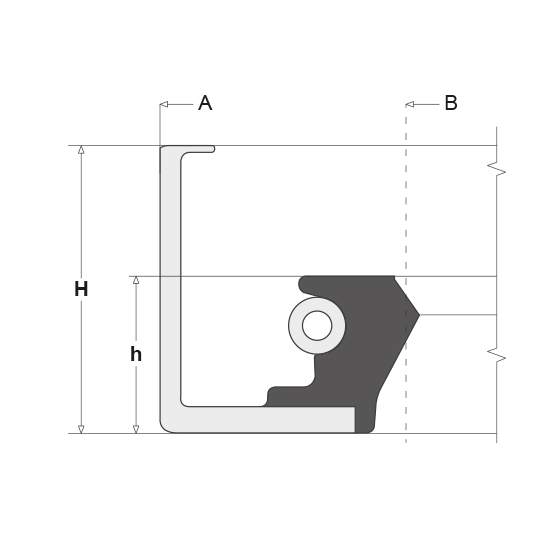

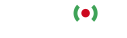

OIL SEALS TYPE L FOR HIGH PRESSURES

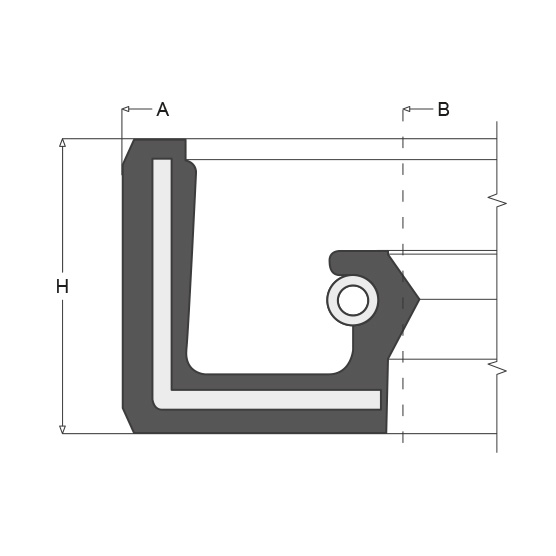

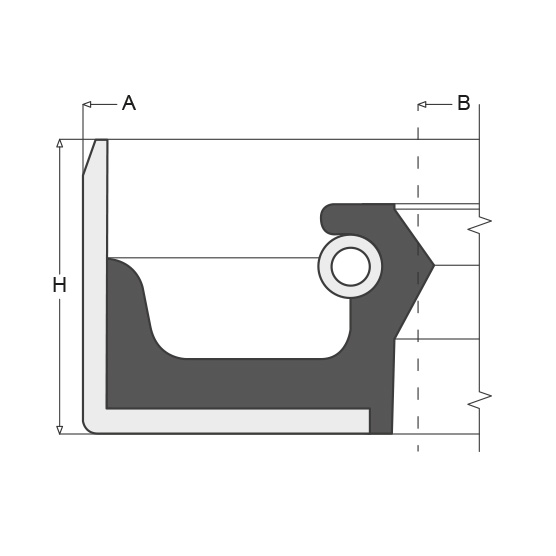

The rotary shaft oil seals type L are proposed in a full range of designs, including the profiles for high pressure applications.

These special profiles are variations of the standard ones, engineered to guarantee excellent performance with such working conditions.

They are named with the extension BP.

Download:

L1-BP

Technical features

Materials

Fe-DC04; AISI 304; AISI 316

AISI 302; AISI 316; C72 phosphased

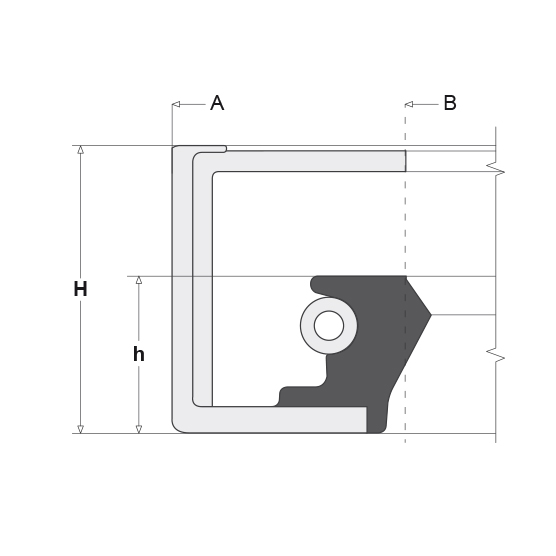

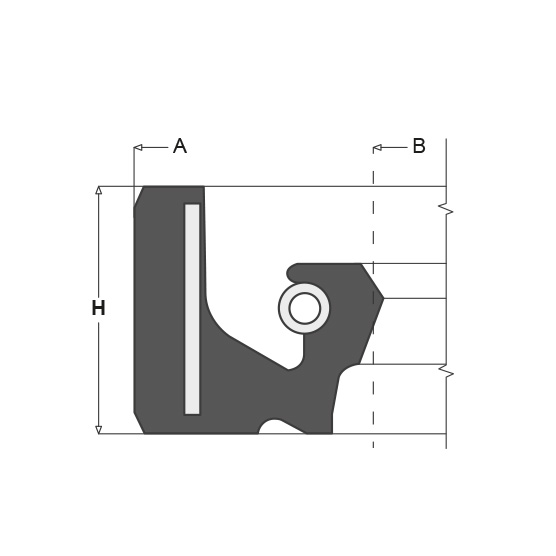

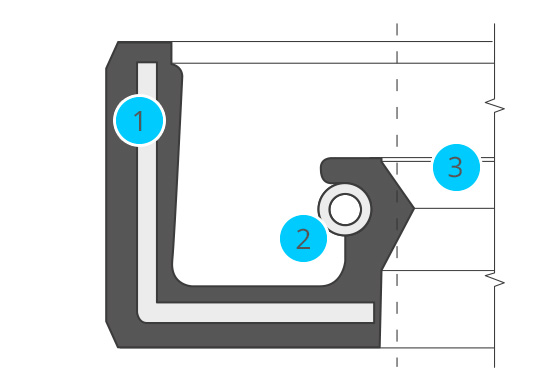

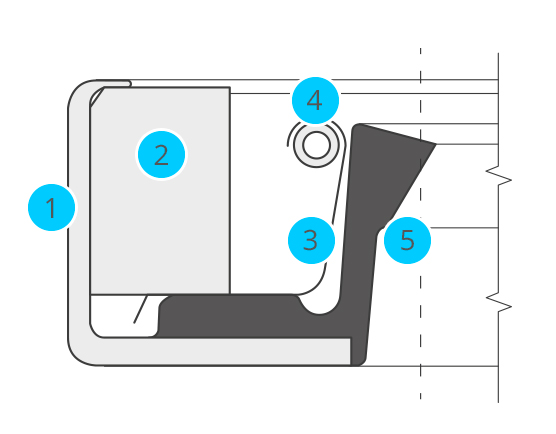

OILS SEALS TYPE L2M® FOR HIGH PRESSURES

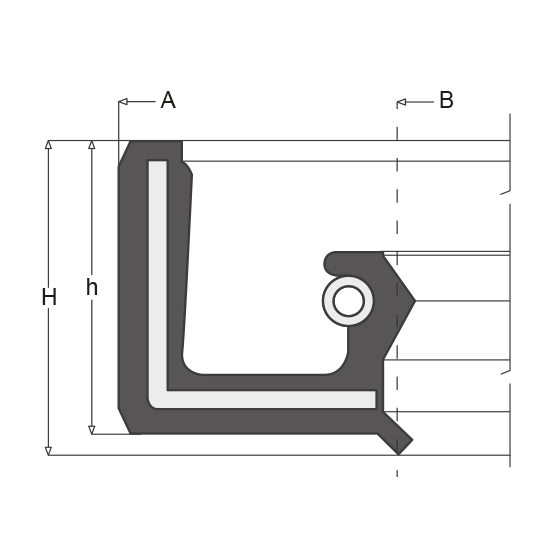

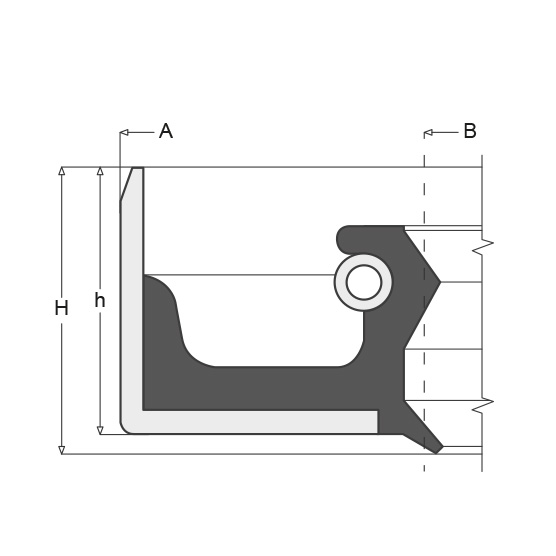

The rotary shaft oil seals type L2M® are proposed in a full range of designs, including the profiles for high pressure applications.

These special profiles are variations of the standard ones, engineered to guarantee excellent performance with such working conditions.

They are named with the extension BP.

Download:

L2M-BP

Technical features

Materials

Fe-DC04

Fe 37

AISI 301

AISI 316

NBR; HNBR; FKM; VMQ

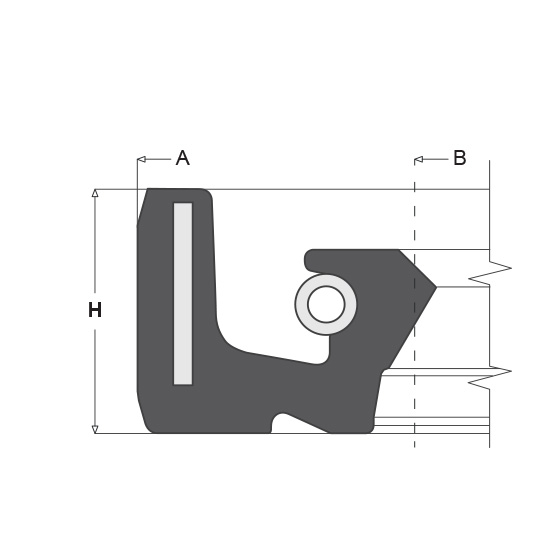

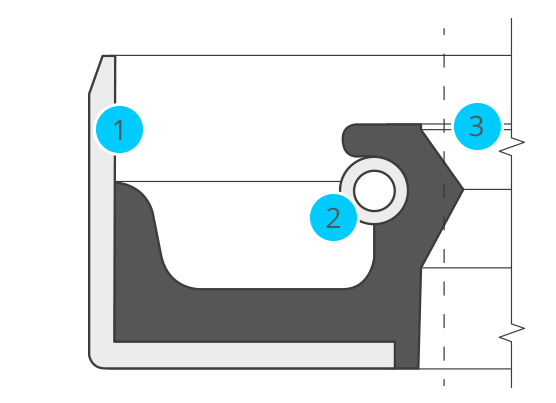

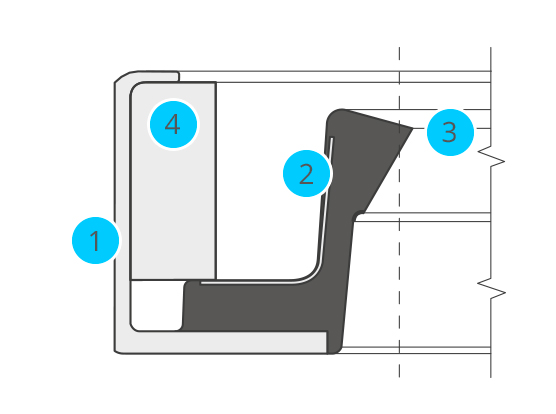

OILS SEALS TYPE L1M FOR HIGH PRESSURES

The rotary shaft oil seals type L1M are proposed in a full range of designs, including the profiles for high pressure applications.

These special profiles are variations of the standard ones, engineered to guarantee excellent performance with such working conditions.

They are named with the extension BP.

Download:

L1M-BP

Technical Features

Materials

OIL SEALS TYPE TGF FOR HIGH PRESSURES

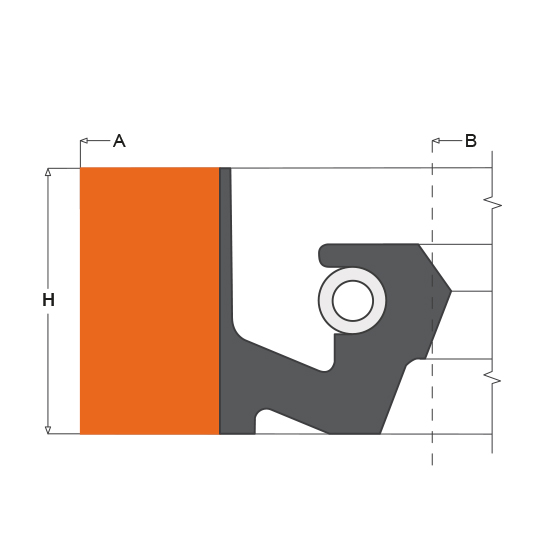

•FP• produces a full range of TGF oil seals designs, including the profiles for high pressure applications.

These special profiles are variations of the standard ones, engineered to guarantee excellent performance with such working conditions.

They are named with the extension BP.

Download:

TGF-BP

Technical features

Materials

NBR; FKM; HNBR

Fe C67 temperato

AISI 302; AISI 316